What Is MDF(Medium Density Fiberboard)?

Medium Density Fiberboard (MDF), a crucial engineered wood product developed in the late 20th century, has become a cornerstone material in modern furniture manufacturing, interior construction, and decoration due to its excellent physical properties, high workability, cost-effectiveness, and increasingly enhanced environmental characteristics. This report aims to provide a comprehensive, in-depth, and forward-looking professional analysis. Starting from the basic definition, core technical specifications, manufacturing process, and main application areas of MDF, it delves into the latest technological advancements as of 2025, particularly focusing on key issues such as environmental standards, functional development, and sustainability.

- Research Report: Comprehensive Analysis of Medium Density Fiberboard (MDF) – From Core Technology to Cutting-Edge Applications

- Abstract

- Chapter 1: Basic Definition and Core Characteristics of MDF

- 1.1 What is Medium Density Fiberboard?

- 1.2 Physical Properties: Density and Mechanical Performance

- 1.3 Environmental Characteristics: Analysis of Formaldehyde Emission Standards

- Chapter 2: Comprehensive Analysis of the MDF Manufacturing Process

- 2.1 Raw Material and Fiber Preparation

- 2.2 Forming and Hot Pressing: The Decisive Step for MDF Performance

- 2.3 Finishing

- Chapter 3: Main Industrial Application Areas of MDF (As of 2025)

- Chapter 4: Technological Frontiers: Functional and Sustainable MDF (2025 Perspective)

- 4.1 Low-Formaldehyde/Formaldehyde-Free Technology and Environmental Upgrades

- 4.2 Functional MDF: Meeting Specific Scenario Demands

- 4.3 Sustainability: Biomass Utilization and Circular Economy

- Chapter 5: Conclusion

Research Report: Comprehensive Analysis of Medium Density Fiberboard (MDF) – From Core Technology to Cutting-Edge Applications

Abstract

Medium Density Fiberboard (MDF), a crucial engineered wood product developed in the late 20th century, has become a cornerstone material in modern furniture manufacturing, interior construction, and decoration due to its excellent physical properties, high workability, cost-effectiveness, and increasingly enhanced environmental characteristics. This report aims to provide a comprehensive, in-depth, and forward-looking professional analysis. Starting from the basic definition, core technical specifications, manufacturing process, and main application areas of MDF, it delves into the latest technological advancements as of 2025, particularly focusing on key issues such as environmental standards, functional development, and sustainability.

Chapter 1: Basic Definition and Core Characteristics of MDF

1.1 What is Medium Density Fiberboard?

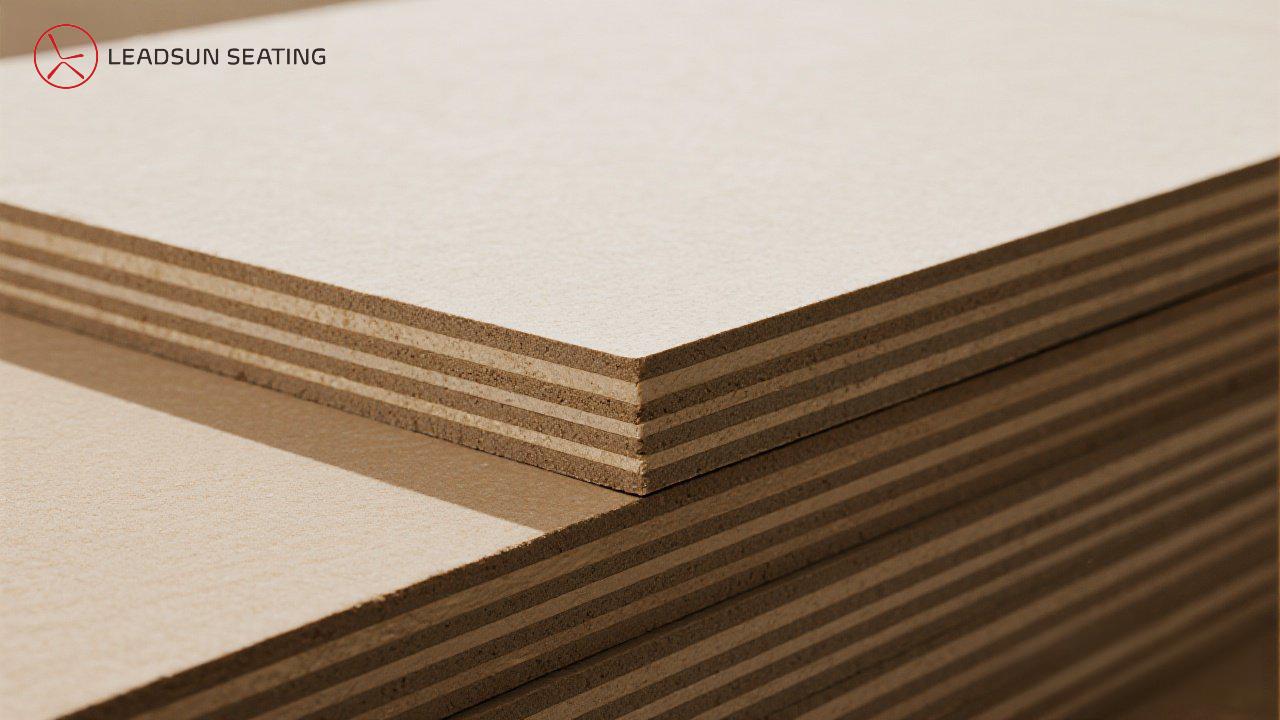

Medium Density Fiberboard is an engineered wood product (panel) primarily made from wood fibers or other plant fibers (such as small-diameter logs, logging residues, bamboo, bagasse, etc.). These fibers are broken down, separated, and dried, then mixed with synthetic resins (mainly urea-formaldehyde resin, or more environmentally friendly alternatives like isocyanate resin, melamine resin, etc.) and other additives (such as wax for water resistance). The mixture is then pressed under high temperature and high pressure to form panels .

Compared to particleboard, MDF has a more uniform and fine internal structure without granular elements. Compared to solid wood, it overcomes inherent defects like knots, wormholes, and grain directionality, offering stable physical properties and resistance to cracking and warping. Its surface is extremely smooth and flat, providing an excellent substrate for subsequent finishing treatments (such as painting, laminating, PVC foiling, etc.) .

1.2 Physical Properties: Density and Mechanical Performance

The core characteristics of MDF are determined by its density. According to international standards and industry practices, the density specification of MDF directly affects its physical and mechanical properties and application scenarios.

-

Density Range and Classification:

- General Range: According to the ANSI A208.2 standard by the American National Standards Institute (ANSI), MDF density typically ranges from 500 kg/m³ (31 lbs/ft³) to 1000 kg/m³ (62 lbs/ft³). European standards indicate that the average density of MDF panels usually falls between 700 to 800 kg/m³.

- Industry Classification: Typically, the industry further subdivides fiberboards based on density:

- High-Density Fiberboard (HDF): Density above 800 kg/m³.

- Medium-Density Fiberboard (MDF): Density between 650 kg/m³ to 800 kg/m³.

- Low-Density Fiberboard (LDF): Density below 650 kg/m³.

- Ultra-Low-Density Fiberboard (ULDF): Density below 550 kg/m³.

-

Mechanical Performance: Due to its uniform fiber structure, MDF possesses excellent physical and mechanical properties. Its modulus of rupture (MOR), internal bond strength (IB), and modulus of elasticity (MOE) are high. It also has strong screw holding capacity, can withstand significant loads and pressure, and outperforms particleboard of equivalent thickness . Furthermore, it exhibits good dimensional stability, with low rates of expansion and contraction under varying temperature and humidity conditions .

-

1.3 Environmental Characteristics: Analysis of Formaldehyde Emission Standards

Formaldehyde is a chemical present in the adhesives (mainly urea-formaldehyde resin) used in MDF production. Its emission level directly impacts indoor air quality and human health. Therefore, strict formaldehyde emission limits have been established globally. As of 2025, the mainstream standards and their limits are as follows:

-

Chinese National Standard (GB): China has aligned its formaldehyde emission standards for wood-based panels with the highest international levels, establishing a comprehensive tiered system:

- ENF Grade (≤ 0.025 mg/m³): One of the strictest formaldehyde emission standards globally, representing the highest level of "No Added Formaldehyde" (NAF) panels.

- E0 Grade (≤ 0.050 mg/m³): This is the level specified in the latest mandatory national standard GB 18580-2025, effective from June 1, 2026, imposing higher environmental requirements for indoor wood-based panels.

- E1 Grade (≤ 0.124 mg/m³): This is the basic environmental grade for market access; panels meeting this standard can be used directly indoors.

-

European Standard (EN): European standards are an important international reference.

- E1 Grade (≤ 0.124 mg/m³): According to EN 13986, E1 is the common standard in Europe, with the same limit as the Chinese E1 grade.

- E0 Grade: There is no official "E0" grade in European standards. However, the industry generally considers products with formaldehyde emissions significantly lower than E1 as E0, e.g., some specifications require emissions not exceeding 65% of the E1 level.

-

American Standard (ANSI/CARB): The US primarily uses the California Air Resources Board (CARB) standards, implemented nationwide under the federal Toxic Substances Control Act (TSCA Title VI).

- Standards are typically expressed in ppm (parts per million). For example, ANSI A208.2 defines grades like "-F11", representing a maximum formaldehyde emission level of 0.11 ppm.

-

Unit Conversion and Understanding:

ppmtomg/m³Conversion: Conversion between these units depends on temperature and pressure. Under standard conditions (e.g., 25°C, 1 atm), the approximate relationship for formaldehyde is: 1 ppm ≈ 1.24 mg/m³. Therefore, the US 0.11 ppm standard equates to approximately 0.136 mg/m³, slightly higher than the Sino-European E1 standard.- Understanding

mg/100g: This unit, measured by the "Perforator Method" (e.g., EN 120), quantifies the "extractable" formaldehyde content from the panel itself, not the direct concentration released into the air. There is no simple mathematical conversion formula betweenmg/100gandmg/m³(measured by the Chamber Method), as they represent different testing logics. However, they are correlated and often used by manufacturers for internal quality control. The ISO 12460 series are internationally recognized test methods, but the standard itself does not provide an official methodology for converting between these different dimensional units.

Chapter 2: Comprehensive Analysis of the MDF Manufacturing Process

MDF production is a highly automated and precisely controlled process, mainly consisting of four stages: raw material preparation, fiber preparation, forming & hot pressing, and finishing.

2.1 Raw Material and Fiber Preparation

The process begins by chipping logs or other raw materials into specific sizes. The chips are screened to remove impurities and then fed into a defibrator (refiner). Inside the defibrator, chips are softened by steam cooking under high temperature and pressure, then mechanically ground into fine fibers. Liquid resin (adhesive) and wax (water repellent) are then uniformly sprayed onto the fiber surfaces within a pipeline. The resinated fibers are conveyed by high-speed airflow into a dryer to achieve the required moisture content (typically 8%-12%) .

2.2 Forming and Hot Pressing: The Decisive Step for MDF Performance

This is the most critical stage in MDF manufacturing. The dried fibers are uniformly distributed onto a conveyor belt, forming a mat of consistent thickness. This fiber mat passes through a pre-press to achieve initial compaction and remove most of the air. Subsequently, the mat is fed into a large multi-opening hot press or a continuous press.

Under set high temperature and high pressure within the press, the resin between the fibers cures, bonding the loose fibers into a rigid panel of predetermined density and thickness. The three key parameters of hot pressing – Temperature, Pressure, and Time – collectively determine the final physical properties of the MDF.

-

Relationship Between Pressing Parameters and Density:

- Temperature: Typically between 160°C to 220°C. Higher temperatures accelerate resin curing and help form a denser surface layer, but excessive heat can darken the panel or reduce strength.

- Pressure: Typically between 2.5 MPa to 5.5 MPa. Pressure directly influences the degree of compaction, thus determining the final density. By precisely controlling the pressure profile (e.g., applying high peak pressure at the start of pressing, then gradually reducing it), a specific vertical density profile (VDP – higher density near surfaces, lower in the core) can be achieved to optimize bending strength and internal bond.

- Time: Pressing time ranges from tens of seconds to several minutes, primarily depending on panel thickness, resin type, and pressing temperature. Thicker panels require longer heating times to ensure the core fully cures.

-

Hot Pressing Parameters for Different Density MDF:

- Low Density (LDF, <650 kg/m³): Typically uses lower temperatures (e.g., 160°C - 170°C) and pressure, with moderate pressing times to avoid over-compaction.

- Medium Density (MDF, 650-800 kg/m³): Generally employs temperatures of 190°C - 200°C and pressure around 3.5 MPa, with pressing time adjusted for thickness.

- High Density (HDF, >800 kg/m³): Requires higher temperatures (e.g., near 200°C or above) and greater pressure to achieve high densification.

While standards like ISO 16895:2016 exist for MDF testing, there is currently a lack of publicly available, empirically verified databases certified under such standards that directly correlate specific pressing parameters with different density grades. Manufacturers typically rely on empirical models and extensive experimental data to optimize process parameters for their specific production lines.

2.3 Finishing

The pressed panels undergo cooling, trimming to exact size, and sanding to achieve precise dimensions and a smooth surface finish. Finally, based on quality inspection results, panels are graded and packaged for shipment.

Chapter 3: Main Industrial Application Areas of MDF (As of 2025)

Leveraging its outstanding performance and economy, MDF plays an indispensable role in numerous industries.

-

Furniture Manufacturing: This is the largest and most significant application area for MDF. It is the material of choice for mass-produced panel furniture (e.g., wardrobes, bookcases, TV cabinets) as well as intricately designed custom or office furniture. The growth in global demand for modular furniture further expands MDF's prospects.

-

Construction and Interior Decoration: MDF is widely used in various aspects of interior non-load-bearing structures.

- Walls and Partitions: Used for decorative wall panels, acoustic panels, partition walls.

- Doors: Commonly used as the core for molded door facings or as the core material for flat doors.

- Moldings and Trim: Favored for making skirting boards (baseboards), crown moldings, door/window casings due to its ease of shaping and painting.

- Flooring: High-Density Fiberboard (HDF) is the primary core material for laminate flooring.

-

Cabinet Manufacturing: Kitchen and bathroom cabinets represent another massive market for MDF, estimated to account for 25-30% of total market share. Its smooth surface is ideal for painting, laminating, or thermofoiling, enabling a wide variety of modern cabinet door styles.

Growth drivers for these applications include increasing global residential construction activity, urbanization, and rising consumer demand for aesthetically pleasing, durable, cost-effective, and environmentally friendly materials.

Chapter 4: Technological Frontiers: Functional and Sustainable MDF (2025 Perspective)

Facing increasingly stringent environmental regulations and diverse market demands, MDF technology is rapidly evolving towards greater environmental friendliness, higher performance, and enhanced sustainability.

4.1 Low-Formaldehyde/Formaldehyde-Free Technology and Environmental Upgrades

- Eco-Friendly Adhesives: No Added Formaldehyde (NAF) adhesives, such as isocyanates (MDI) or soy-based protein adhesives, have become the technological core of high-end MDF products, capable of reducing formaldehyde emissions to levels comparable to solid wood.

- Process Optimization: Improvements in pressing technology and optimized production line control allow for reducing resin usage and energy consumption while maintaining panel performance, thereby lowering the overall carbon footprint.

- Surface Treatment Innovation: Advances in low-temperature curing powder coating technology enable electrostatic powder coating of MDF at lower temperatures. This not only saves energy but also avoids volatile organic compounds (VOCs) associated with traditional liquid paints, achieving comprehensive environmental friendliness "from core to surface".

4.2 Functional MDF: Meeting Specific Scenario Demands

-

Fire-Retardant MDF (FR-MDF): With rising fire safety standards in public and commercial buildings, demand for FR-MDF has grown significantly. Technical approaches include:

- Adding Flame Retardants: Incorporating inorganic or organic flame retardants containing elements like phosphorus, nitrogen, or boron during production. For example, research shows that adding a 10% (by weight) composite of Magnesium-Aluminum Layered Double Hydroxide (LDHs) and Melamine Polyphosphate (MP) at a 1:1 ratio yields optimal fire resistance.

- Bio-Based and Nanotechnology: Utilizing bio-based materials (e.g., phytic acid, tea polyphenols) or nanomaterials as novel flame retardants. These are not only eco-friendly but can also enable more efficient flame retardancy mechanisms through techniques like microencapsulation.

-

Antibacterial MDF: Has significant potential in high-hygiene settings like hospitals, schools, and public restrooms. However, as of 2025, while academic research has extensively studied various antimicrobial agents and their Minimum Inhibitory Concentration (MIC), peer-reviewed case studies demonstrating the stable, long-lasting, and safe incorporation of specific antimicrobial agents (with clear types, concentrations, and MIC thresholds) into industrial-scale MDF production remain very limited (Ref. 15, 17, 18). This indicates that antibacterial MDF is still in a critical transition phase from lab R&D to industrial application, representing an important future technological breakthrough direction.

4.3 Sustainability: Biomass Utilization and Circular Economy

- Raw Material Diversification: Utilizing non-traditional biomass resources like agricultural residues (e.g., straw), fast-growing plantations, and recycled wood to produce MDF is a vital pathway for reducing deforestation and promoting the circular economy.

- Recycling of Waste MDF: Technologies for recycling waste MDF are becoming a research hotspot. Main approaches fall into two categories:

- Physical Recycling: Shredding waste MDF into fibers for reuse in new MDF production. Research indicates that incorporating up to 20% recycled fiber is feasible without significantly compromising new panel performance.

- Chemical Recycling: Utilizing techniques like pyrolysis to convert waste MDF into higher-value products such as biochar, bio-oil, and syngas, enabling resource and energy recovery.

-

Chapter 5: Conclusion

Medium Density Fiberboard (MDF), as a mature yet continuously evolving engineered material, offers value far beyond being merely a cheap wood substitute. It achieves an intricate balance between performance, cost, and workability, deeply integrating into our daily lives over the past decades.

Looking ahead, as of 2025, the main themes driving the MDF industry are clear and distinct: Greening, High-Performance Functionality, and Circularity. With the widespread adoption of ultra-low formaldehyde standards exemplified by China's ENF grade, MDF is shedding the stereotype of being "unenvironmental." The continuous maturation of functional products like fire-retardant and antibacterial MDF will further expand its application boundaries. Breakthroughs in recycling technology will allow it to perfectly align with the global sustainability agenda.

It is foreseeable that MDF will continue to be a staple material, playing an increasingly vital role in the future of sustainable construction and green furniture industries.

The Future of Reception Areas: 10 Modern Waiting Room Chair Trends to Watch in 2026

Airport Seating Reimagined: The 2026 Global Guide to Terminal Comfort and Design

7 Costly Mistakes Facilities Managers Make When Specifying Commercial Bench Seating

Commercial Beam Seating Solutions for High-Traffic Public Spaces

The Ultimate Guide to Waiting Area Chairs: Design, Durability, and Discerning Choices for 2026

FAQs

How can I request a quote for a seating project?

You can easily request a quote by contacting our sales team through our website or by email. Provide details about your project, including the quantity and specific requirements, and we will get back to you with a tailored quote.

Are your products compliant with safety and accessibility standards?

-

Absolutely. All of our seating solutions comply with relevant safety regulations and accessibility standards, ensuring comfort and safety for all users, including those with special needs.

-

One Stop Airport Terminal Seating

How long is the production cycle? Can you deliver on time?

The production cycle depends on the order size and customization complexity. We’ll create a detailed production plan in advance and have a professional logistics and installation team in place to ensure on-time delivery and efficient implementation.

What are the advantages of the one-stop solution compared to traditional procurement methods?

The one-stop solution integrates the entire service process, saving communication costs and time. It avoids coordination issues that arise when working with multiple parties and ensures consistency and coherence in design, production, and after-sales service.

Are there any successful cases we can refer to?

We’ve provided services to numerous international and major domestic airports. We can offer detailed case materials, on-site photos, and client testimonials, so you can get a clear understanding of the solution’s effectiveness.

LS-550 Comfortable and Durable Waiting Chair | Customizable Waiting Chair Supplier Leadsun Seating

The LS-550 waiting chair from Leadsun offers superior comfort and durability for any public place. Customize your seating with Leadsun, a leading customizable waiting chair supplier. Ideal for high-traffic areas, the LS-550 ensures lasting performance and style.

LS-908 Series Fixed Public Auditorium Chair or Tiered Classroom Solutions by Leadsun Seating

LS-9301 Single movable classroom chair |The Ultimate Flexible Solution for Modern Classrooms by Leadsun Seating

LS-551 Ergonomic Modular Waiting Chairs | Commercial Seating Solutions by Leadsun Seating

Ready for your public seating project?

We specialize in providing high-quality, customizable seating solutions for public spaces, and we are excited to assist you with your project.

Our professional team will quickly answer your questions and provide customized solutions to ensure you have a worry-free experience.

Scan QR Code

Scan QR Code